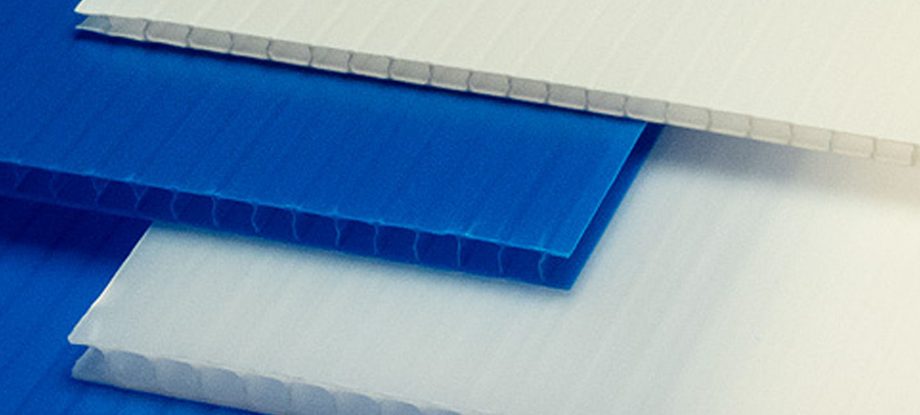

K-Protect PP (Polypropylene) Sheet

K-protect PP sheet is a durable, versatile, and cost-efficient material widely used in the construction industry for protecting floors, surfaces, and delicate materials during the building process. Its unique design features flute ridges and flat backing layers, provide excellent cushioning and shielding properties, making it an invaluable asset on construction sites.

Using K-Protect PP Sheet during construction significantly reduces the risk of damage to floors, surfaces, and fixtures. It acts as a protective barrier against scratches, stains, and impact from heavy equipment, tools, and foot traffic. By preventing surface damage, it minimizes repair and cleaning costs post-construction, delivering substantial savings for contractors and clients.

Technical Characteristics

-

Dimensions: 2x1m (2m2)

-

Density: 350 Gr/m2

-

Available Thickness: 22mm Ask for other thickness

Applications

-

Protecting flooring, including tiles, hardwood, or concrete surfaces.

-

Shielding surfaces of retaining walls, columns, and other structural elements.

-

Protecting waterproofing layers, they are used to shield waterproofing membranes during construction, preventing damage and ensuring the integrity of waterproofing systems on floors, retaining walls, and other surfaces.

-

Covering and cushioning materials during transportation or storage.

-

Temporary protection during renovations or remodeling projects.

Key Benefits

-

Cost-Effective: Reduces damage-related expenses and cleanup time.

-

Reusable and Durable: Designed for multiple uses across different projects, providing long-term value.

-

Easy to Install and Remove: Lightweight and flexible, facilitating quick setup and dismantling without damaging surfaces.

-

Adaptable: Suitable for irregular shapes and various surface types, ensuring comprehensive protection.

Sustainability

K-protect PP sheet is recognized for its environmentally conscious properties. Polypropylene is a thermoplastic polymer that can be recycled multiple times, supporting sustainable construction practices. Its durability extends the lifespan of the protection it provides, reducing the need for frequent replacements and minimizing waste. Additionally, the manufacturing process of polypropylene involves lower energy consumption compared to other plastics, and it produces fewer greenhouse gases. When properly recycled at the end of its life cycle, PP sheets contribute to circular economy initiatives, helping to reduce environmental impact and promote resource efficiency in construction projects.